Biogas, primarily composed of methane, is produced through the anaerobic digestion of organic materials such as agricultural waste, food scraps, and sewage. With its potentials to be injected into the natural gas grid , used as a vehicle fuel, and help manage organic waste, reduce greenhouse gas emission, governments around the world are implementing policies and incentives to encourage the development of biogas and improvement of biogas production technologies.

| Region | Action | Key Points | Date |

| United States | The Biogas Research and Development Act | Aims to advance the development of biogas as a renewable energy source. | 2019 |

| European Union | EU Landfill Directive | Requires member states to reduce the amount of biodegradable waste sent to landfills by 65% by 2035. | 1999 |

| European Union | EU Renewable Energy Directive (RED III) | Sets targets, regulatory frameworks, and guidelines for the development and use of renewable energy sources (including biogas and biomethane) across the EU in 2021-2030. | 2021 |

| Germany | EEG (Renewable Energy Sources Act) | Introduced a feed-in tariff (FiT) system, guaranteeing fixed payments for renewable energy producers. | 2021 |

| United Kingdom | Green Gas Support Scheme (GGSS) | Aimed to encourage the production of biomethane from renewable sources such as agricultural waste, food waste, and sewage sludge. | 2021 |

| Brazil | Regulatory Framework for Biomethane (ANP Resolution 43/2018) | Addresses the rules and guidelines for the production, distribution, and commercialization of biomethane in the Brazilian energy market. | 2018 |

| India | National Biogas and Manure Management Program | The program encourages the establishment of biogas plants at the household and community levels. | 2009 |

| Thailand | Alternative Energy Development Plan | Aims to increase the share of renewable energy in Thailand's energy mix. It includes measures to promote biogas to reduce greenhouse gas emissions and improve energy security. | 2015 |

| Indonesia | Bioenergy Development Strategy | Strategy for bioenergy development includes the expansion of biogas from agricultural waste, aiming to improve rural energy access and reduce dependence on fossil fuels. | 2020 |

Beside the aboved activated policys and incentives, more and more new acts and regulations will be adopted to encourage biogas production and set standards for biomethane injection around the world, the importance of biogas and biometahne analysis cannot be overstated. Reliable biogas anaysis solutions provided by Cubic can help to ensure the safe, efficient, and sustainable production of biogas, while simultaneously meeting regulatory standards and fostering environmental and economic goals.

Biogas, primarily composed of CH4 and CO2, along with trace gases such as H2S, CO and H2, is typically produced from organic materials like agricultural waste, food waste, manure and sewage sludge in a sealed, oxygen-free digester, where it is broken down by anaerobic microorganisms. Regular measurement of the gas composition at this stage helps in understanding the efficiency of the digestion process and optimizing conditions (temperature, pH, etc.) for maximum biogas yield. It also helps in detecting unwanted components like H2S, which can cause corrosion and damage to equipment later in the process.

Handheld biogas analyzer Gasboard-3200Plus is designed for daily inspection use for biogas production efficiency and quality check at different biogas sites.

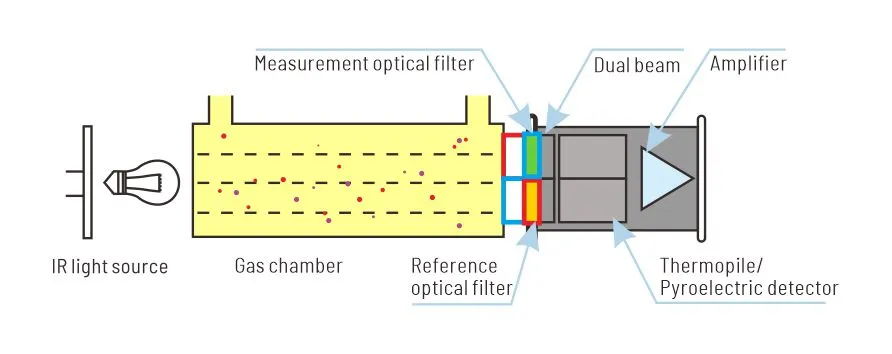

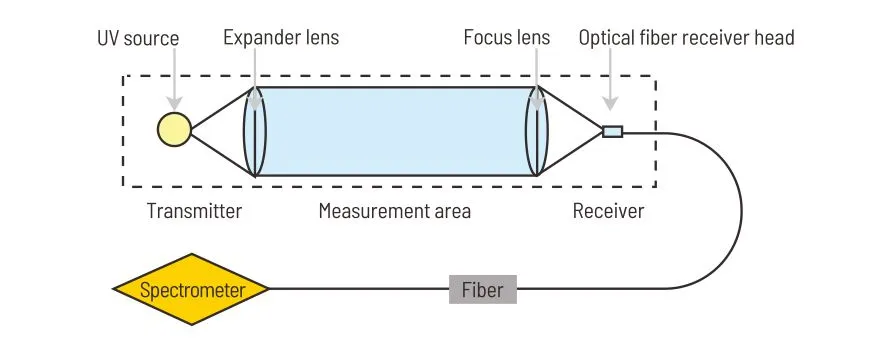

Hydrogen sulfide (H2S) is a common contaminant in raw biogas and can be corrosive to pipeline infrastructure and affect the combustion process when the biogas is used as a fuel, thus desulfurization is a vital stage in the whole process flow. Monitoring gas composition before and after desulfurization is essential to ensure that H2S levels are sufficiently reduced to meet pipeline specifications. and helps in adjusting desulfurization processes to optimize performance and prevent over-treatment. Based on advanced UV-DOAS and NDIR technologies,continuous biogas analysis system Gasboard-3500UV with dual H2S measurement range and multiple sampling channel, is a ideal solution to monitor H2S and CH4 content before and after desulfurization scrubber

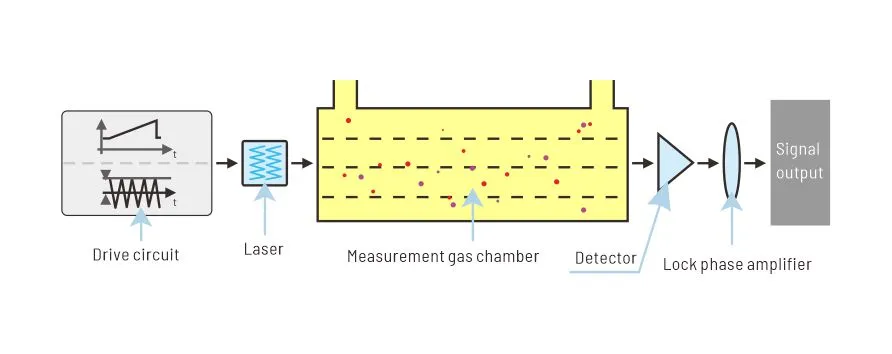

Purification process involves removing CO2, moisture, and other impurities to upgrade biogas to a quality suitable for gas engines, turbines or injection into the natural gas grid . The goal is to increase the methane content of the biogas, which improves its calorific value and makes it comparable to natural gas. Thus monitoring the CH4 and CO2 concentrations during purification is vital for assessing and improving the effectiveness the process. Adopted the innovative TDLAS, Cubic's bio-methane gas analyzer Gasboard-3200L / Gasboard-3500 is able to provide 0-100% CH4 measurement with ultra high accuracy (±0.5%). It is a important tool to ensures the final product meet the standards of natural gas and eventual use equipment.

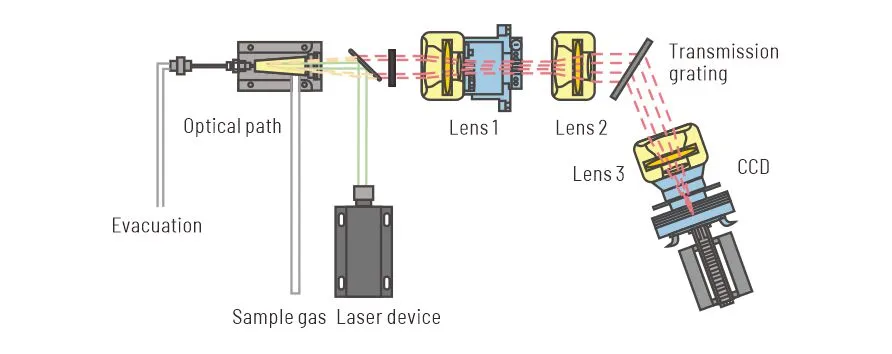

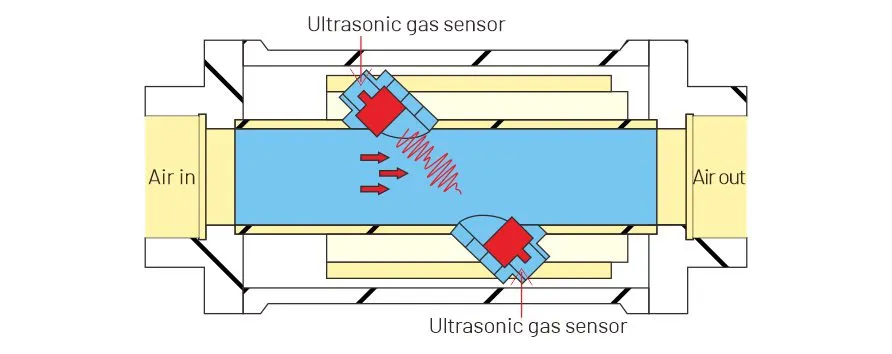

Upgraded biogas or biomethane can be used for power and heat generation, transportation fuels, natural gas grid injection and chemical production. These applications also involve gas composition and flow rate measurement. Before grid injection, continuous monitoring of gas composition ensures compliance with pipeline quality standards. After injection, gas analysis instruments are also needed to check the heat value of biogas and natural gas mixtures. Laser Raman gas analyzer LRGA-3100 and Laser Raman analysis system LRGA-6000 can accurately measure CH4, CO2 and C2-C4 hydrocarbons and calculate heat value, helping operators adjust gas mixture process and avoid end users' complaints. Cubic also offers ultrasonic biogas flow meters BF-3000 to track biogas yield and consumption, assess system health, and manage gas storage or usage effectively.

Real time mesurement of biogas composition and concentration allows the operators continuously assessing process conditions and adjustments can be made according to improve efficiency and output.

Biomethane must meet certain specifications, especially if it's being injected into the natural gas grid or used as a vehicle fuel. Regular monitoring helps ensure that methane content remains high and impurities are within acceptable limits.

Biogas composition and flow rate monitoring provides verifiable data for carbon credits or renewable energy incentives, supporting the economic viability of biogas projects.

Continuous monitoring helps detect deviations from normal operating conditions , which can indicate potential failures in equipment or the biological process. Early detection allows for preventive maintenance and reduces downtime.

Contact Cubic Sensor to Explore Innovative Methane Gas Sensing Solutions!

inquiry@gassensor.com.cn

inquiry@gassensor.com.cn

+86-27-81628827

+86-27-81628827

Fenghuang No.3 Road, Fenghuang Industrial Park, Eastlake Hi-tech Development Zone, Wuhan, 430205, China

Fenghuang No.3 Road, Fenghuang Industrial Park, Eastlake Hi-tech Development Zone, Wuhan, 430205, China